How to order Straight Box Pleating

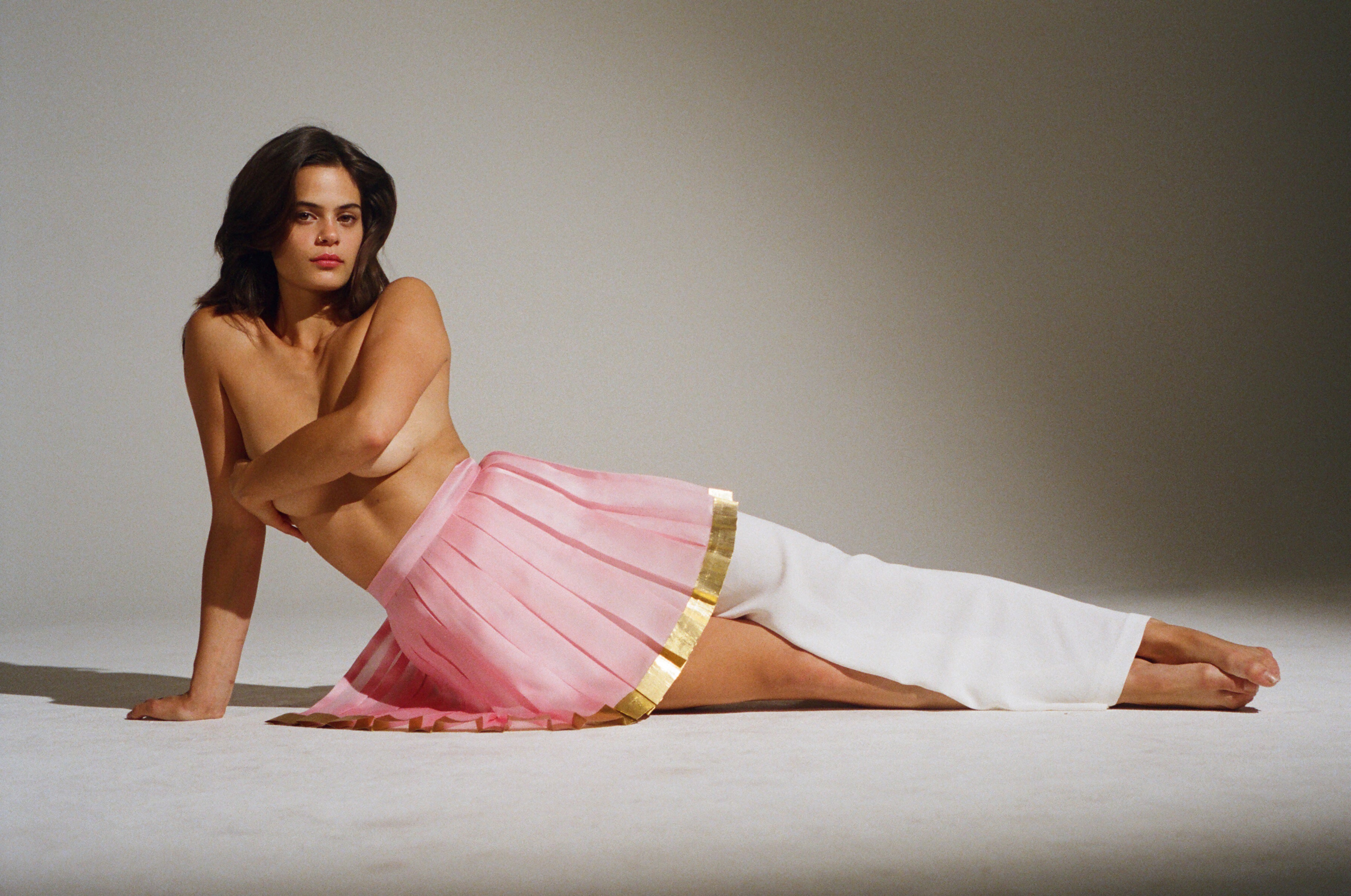

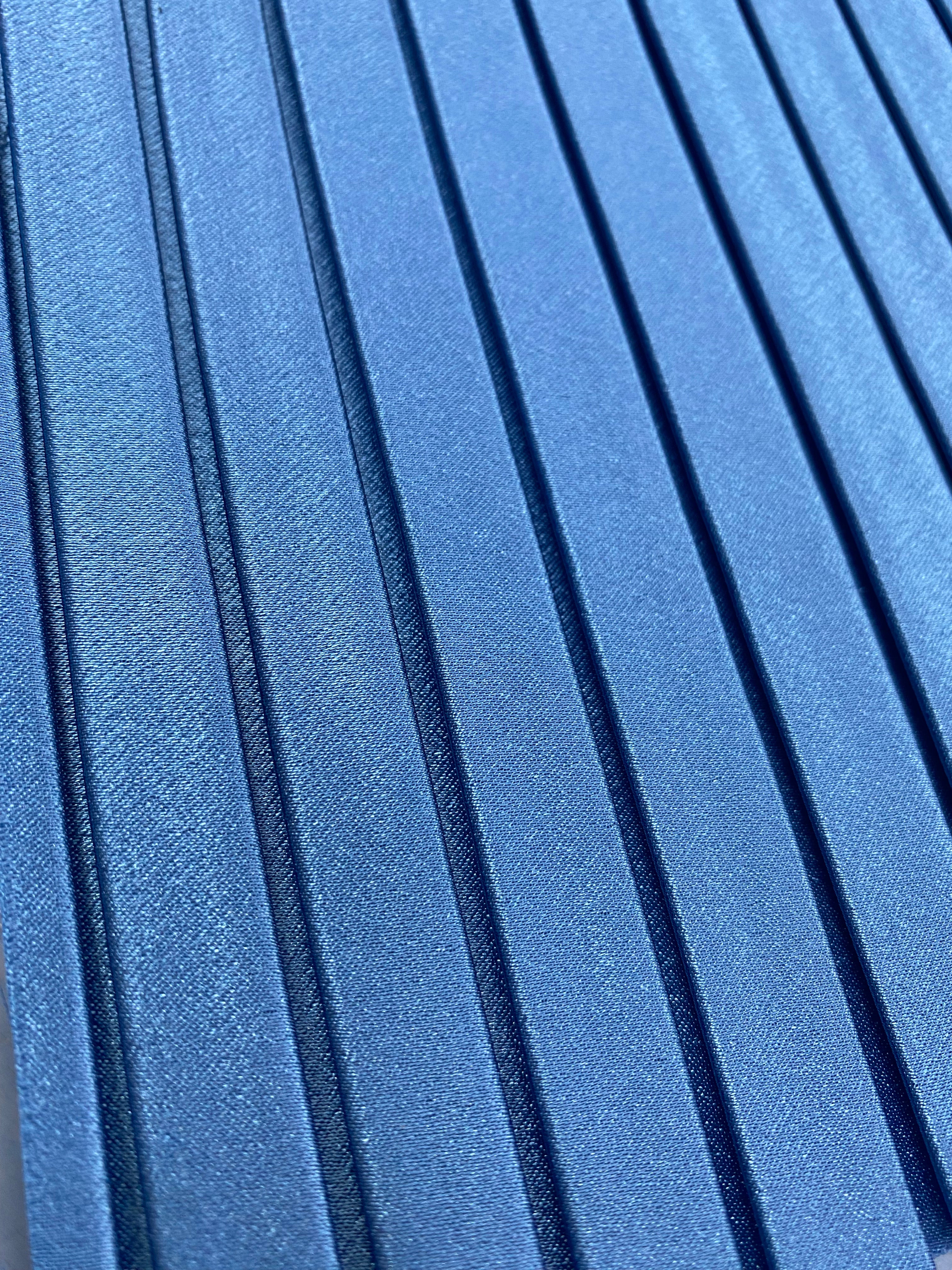

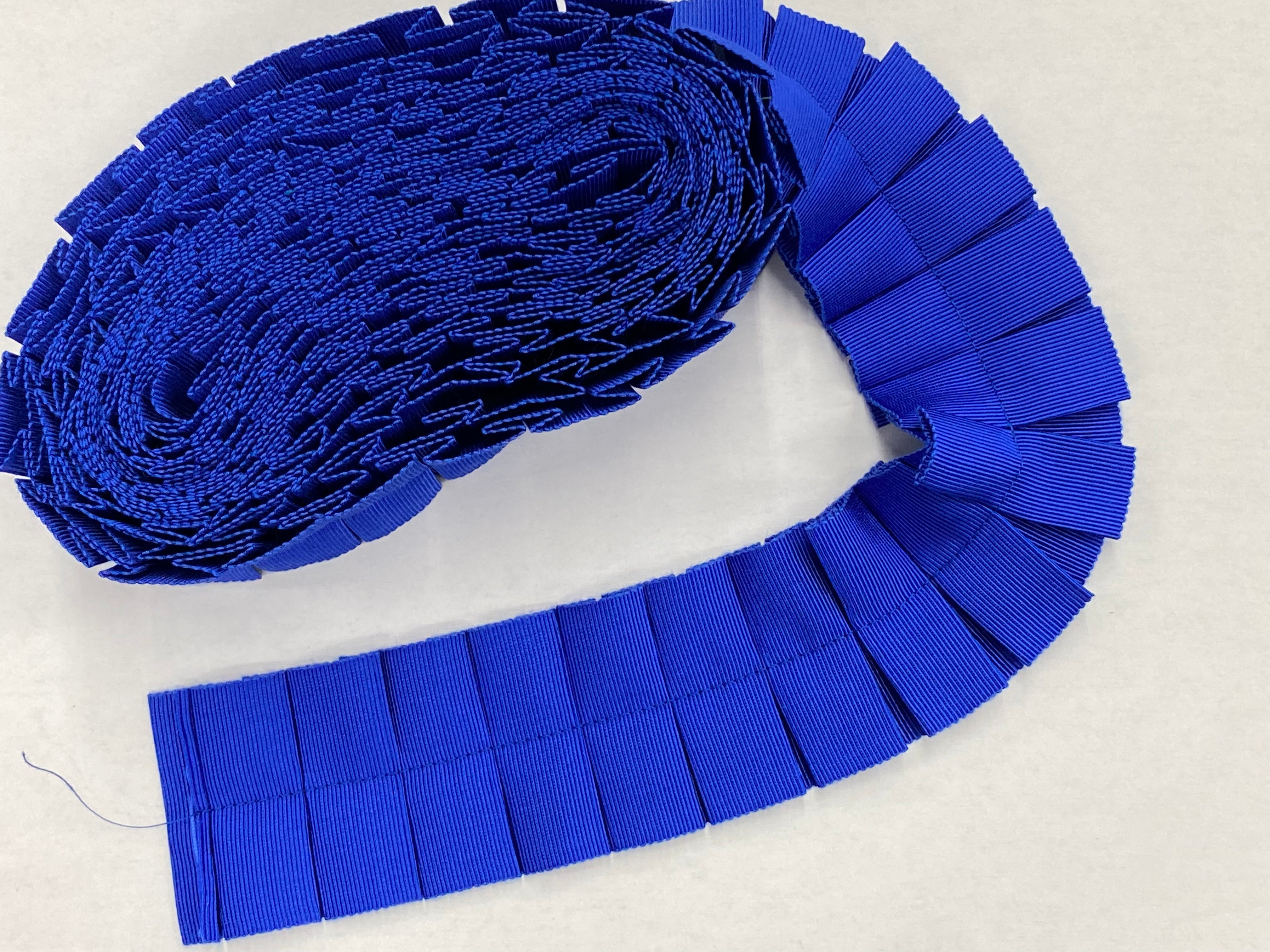

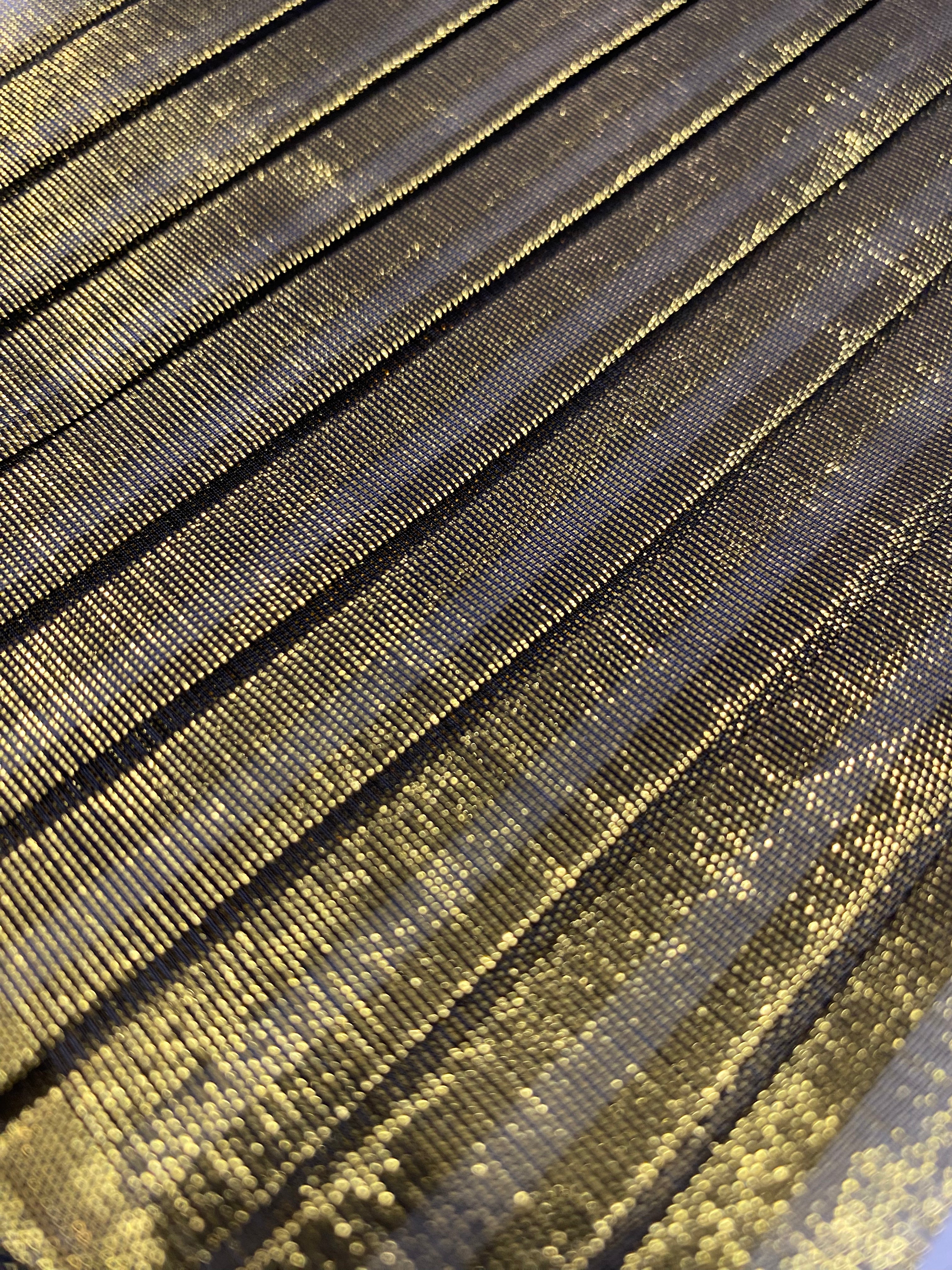

Straight Box Pleating Gallery

Before reading this page, please read How To Order Custom Pleated Fabric.

Once you have decided to order box pleating, follow the steps below to understand the additional steps necessary for calculating and preparing your order. Important facts about box pleating:

- The fabric can be pleated in a mold or by machine. Usually the length of a mold is 4 yards but it could vary depending on the style of the mold. Pleating is done in increments of 4 yards. If pleated by machine the length can be as long as 50 yards.

- The length of the pleat in most molds is 48in. wide. Some molds are available in 60in., 72in. or longer. If pleated by machine, the maximum width is 59in. Please contact us for custom sizes you require.

- The measurements of the pleating are the same along the entire pleat. (From top to bottom).

Step 1. Pick your size and length required. The most common sizes are listed below. If you do not see the size or length you require send us an email (info@internationalpleating.com) to discuss a custom mold.

| Pleat Code | Size |

Mold Dimensions |

Machine |

| G8mm | +1/4in. | N/A | Yes |

| G10mm | 3/8in. | N/A | Yes |

| G12.5mm | 1/2in. | N/A | Yes |

| G15mm | 5/8in. | N/A | Yes |

| G20mm | 3/4in. | 48in. x 4yards | No |

| G25mm | 1in. | 48in. x 4yards | No |

| G30mm | 1 1/4in. | 60in. x 4yards | No |

| G40mm | 1 5/8in. | 48in. x 4yards | No |

| G50mm | 2in. | 48in. x 4yards | No |

Step 2. Determine how much pleated fabric you need. Quantity of fabric is based of the number of garments you are making or your pattern specifications. If you are making a skirt, please provide your hip measurement and skirt length. If you do not have a pattern or tech specs, we also provide Product Development Services.

Step 3. Calculate open yardage. Once you know how many pleated yards you need, you can determine how much "open yardage" is required before pleating. Usually specific pleat styles have a specific "loss factor" or "loss ratio" indicating the amount of fabric that will be used. In most cases, the standard pleating loss factor is 3:1. This means three yards of fabric will yield one yard of pleated fabric. However, we do have the capability to pleat fabric deeper or more shallower in certain sizes. Generally, deeper pleats have a more couture look and than shallower pleats.

Step 4. Choose your fabric quality. This is entirely based on your project needs. However, please consider the following:

- The thinner the fabric, the smaller/finer the pleat size. Thicker fabrics will force you to use larger pleat sizes.

- The thinner/softer the fabric the more flowy it will be. Stiff fabrics have a tendency to get more stiff after pleating.

Step 5. Hemming. If a crisp hem is desired it is usually easier to hem before the pleating is done. This is typically completed before we receive the fabric, but we can provide this service. Keep in mind this will add several days to your order. Things to consider regarding hemming:

- A thick hem could create problems or increase the size of your pleat style.

- If your seamstress stretches the hem during the sewing or pressing process, it could render your fabric useless.

- Thin hems like pearl edge are usually best for medium weight fabrics, whereas thinner fabrics like chiffons could be baby hemmed.

- Pre-hemming machine pleating requires tremendous precision. If not sewn properly, it can damage the fabric and render your fabric useless.

Step 6. Direction of pleating. When pleating fabric in panels, there are several options to choose from. Pleating can be done parallel to the selvedge, perpendicular to the selvedge or along the bias. There are so many variables that determine which is the most suitable, way to many to describe here. However, better constructed garments usually are pleated parallel to the selvedge and less expensive garments are pleated perpendicular to the selvedge. Each case is unique and if you are not sure about the direction, we recommend either working with a professional patternmaker or hiring our Product Development Services.

If you are pleating in panels (parallel to the selvedge), we do not recommend joining panels before pleating. This could lead to the seam falling on the face of the pleat. If you require all the panels joined before pleating we recommend hiring our Product Development Services. For more information regarding this Step, please consult Chapter 8 of Pleating: Fundamentals for Fashion Design.

Step 7. Cutting and prepping your fabric panels. If you are working with a seamstress or a sample room, they should cut the fabric panels to the specs you require and hem the panels so they are ready for pleating. Please ensure that the dimensions of your panels are not larger than our mold dimensions listed in Step 1, and the panels are a true rectangle and not warped due to incorrect cutting, hemming or pressing. Useless fabric can be the result of incorrect prepping or can severely comprise the quality of your pleats. If you do not have a professional sample maker you can hire our Product Development Services.

To order custom box pleating please (larger than 1/2in.-12mm) fill out the Straight Table Pleating Order Form and watch the video instructions below:

To order custom box pleating please (smaller than 1/2in.-12mm) fill out the Machine & Organic Pleating Order Form and watch the video instructions below: